ELITE ROBOTS at Klefinghaus

Hello robots that think, work, and keep pace.

Goodbye monotonous work.

They have earned their place in production halls, laboratories, and logistics centers: lightweight robots that work precisely, collaborate with humans, and quickly adapt to new tasks. These cobots make automation intuitive, compact, and safe. They speed up processes, relieve staff, and open up applications that were previously only possible with great effort. In assembly, in the laboratory, or in packaging, they ensure consistent quality. And they do so around the clock.

With Klefinghaus, you have a partner at your side who understands the technology and thinks along with you during implementation. You receive advice that fits your process, integration that runs smoothly, and delivery you can rely on. The CS, EC, and Palletizer series from ELITE ROBOTS cover a wide range of applications and fit seamlessly into your processes. This ensures measurable efficiency from the very first day of use.

Team efficiency: robots and humans

What is collaborative robotics?

Collaborative robotics means robots supporting humans directly in the workplace. Without protective fences or safety distances, but with sensors that detect movements and stop immediately upon contact. The collaboration is so safe that both can work side by side. This makes processes efficient, precise, reliable, and consistent in quality.

Cobots are smaller, lighter, and quicker to set up than traditional industrial robots. They learn through simple arm guidance or via a graphical user interface. In many cases, a short introduction is sufficient, without any programming experience. Cobots are used wherever they speed up processes and relieve employees. They pack products, sort components, load machines, or check dimensions, weights, and surfaces. The robots take on monotonous and physically demanding tasks. People gain space for what requires skill, decision-making, and experience.

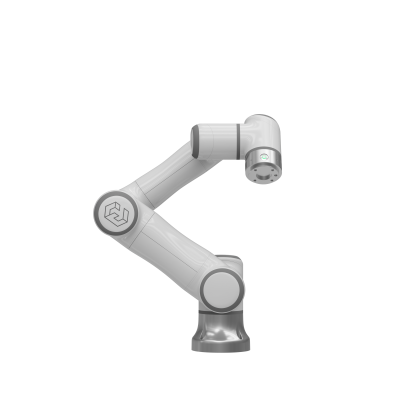

The ELITE ROBOTS series at Klefinghaus

Cobots that think for themselves

They grip, inspect, stack, and sort. They work precisely, keep pace, and can be quickly adapted to new tasks. Cobots from ELITE ROBOTS take over where precision counts and processes must run reliably. Their strength is evident not only in use, but also in selection and integration.

Klefinghaus not only supplies the robots, but also the appropriate peripherals. Grippers, image processing, conveyor technology, and control technology all work together. The entire cell is designed for productivity right from the start.

What does this look like in practice? Here is a look at typical applications where cobots demonstrate their strengths on a daily basis.

Not all cobots are the same

A gripper alone does not constitute a solution. It depends on the interaction between load capacity, reach, cycle time, protection class, image processing, interfaces, and budget. Everything must be suited to the task and to each other. That is why we ask about your process, examine the tasks, and recommend the appropriate model from CS, EC, or Palletizer. We coordinate the grippers, vision systems, and control technology accordingly. We take care of the integration ourselves. The result is a cell that not only works, but also runs productively. Would you like to see what that looks like beforehand? No problem. On request, we can set up a test installation, organize a live demonstration, or show you the solution in one of our demo cells. You will then receive a binding offer with a clear schedule and a designated contact person.

Start, grasp, deliver. ELITE ROBOTS at Klefinghaus.

When you buy a cobot, you want more than just an arm with a motor. It is crucial that everything fits together. That is exactly what Klefinghaus stands for. As an authorized partner of ELITE ROBOTS, we supply tested original products, take care of integration, and support your system throughout its entire life cycle. You get a system that works right from the start and can be further developed during operation.

What you get out of it

- You receive certified technology with a warranty, support, and guaranteed availability of spare parts.

- You plan with fixed delivery times and get what you ordered.

- You work with a contact person who knows your project and sees it through to completion.

- You receive support in every phase of the project—from commissioning to expansion.

- You get more than just robots: control systems, vision systems, grippers, aluminum profiles, and conveyor technology are technically and functionally compatible.

- You remain flexible when requirements change, new products are introduced, or processes need to be adapted.

Klefinghaus doesn't think in terms of components, but in terms of functioning cells. And that's exactly what you get: a solution that grips, delivers, and makes work easy.

FAQ ELITE Robots

What distinguishes a cobot from a traditional industrial robot?

Cobots work directly with humans. They often do not require a protective fence. Sensors and controls limit their force and speed and stop them when touched. Traditional industrial robots are usually located in enclosed areas. Cobots are lighter, more compact, and easier to operate.

How quickly can a cobot be put into operation and how complex is the programming?

Depending on the task and complexity, commissioning takes a few hours to a few days. Operation is via a graphical user interface that is easy to understand. If desired, specific movements can be demonstrated to the robot directly. These are recorded and incorporated into the sequence. Individual functions can also be compiled using drag and drop. In most cases, programming skills are not required.

What are the payload and reach of the models?

Payload and reach determine which tasks a cobot is best suited to perform. ELITE ROBOTS offers various series with their own profiles for this purpose. Here you will find a quick overview to help you find the right solution for your process.

CS Series

Depending on the model, the CS Series can move up to 25 kilograms and reach up to 1,800 millimeters. A CS625 lifts 25 kilograms with a reach of 1,500 millimeters. A CS620 works with 20 kilograms at 1,800 millimeters. The series is available ex works in IP65 and, on request, in IP68.

EC Series

The EC Series covers light to medium loads and offers very long reaches. An EC64-19 achieves 1,900 millimeters with a payload of 4 kilograms. An EC66 delivers 6 kilograms with a reach of around 914 millimeters. The series also includes other models with payloads of around 12 to 16 kilograms and reaches of around 950 to 1,300 millimeters.

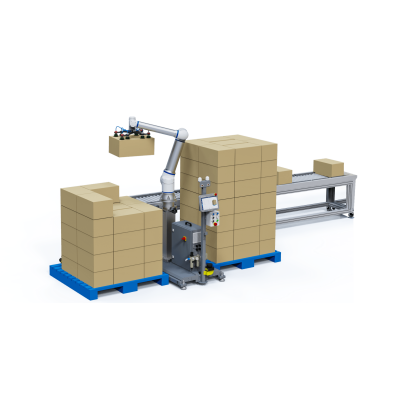

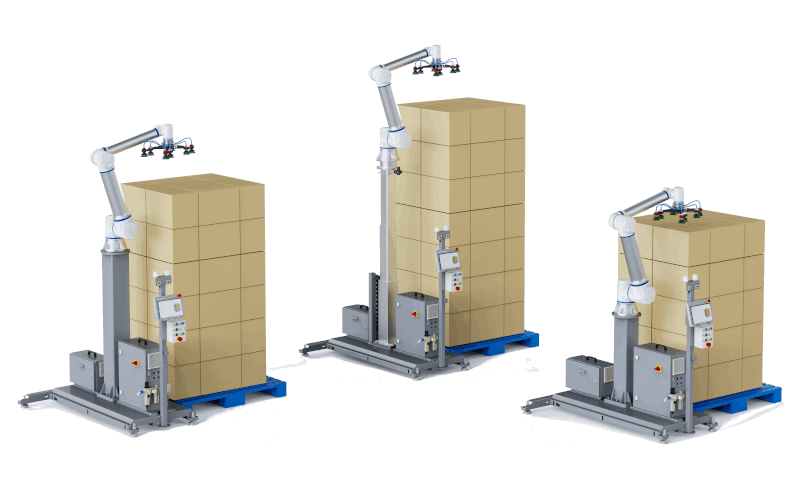

Palletizer

The palletizer has a modular design and is based on the selected robot arm and gripper. In typical configurations, the solution can move up to 30 kilograms. The usable reach is determined by the arm, gripper, and desired stacking height and is around one and a half meters in industrial applications working radius.

How much does a cobot cost and what are the follow-up costs?

Depending on the model, load capacity, and equipment, prices range from around $15,000 to $40,000. In addition, depending on requirements, training, maintenance, and spare parts as well as accessories such as grippers, cameras, or control components may be required. Many applications reduce energy costs and increase throughput. This shortens the payback period.

How safe are cobots when working with humans?

Cobots monitor force and torque. They limit speed and travel. They detect collisions and stop on contact. Standards such as ISO 10218 and ISO TS 15066 specify requirements. Additional scanners and sensors can be added for complex environments.

What maintenance requirements and service life do cobots have?

The effort involved is minimal. Regular inspection, lubrication, and calibration are sufficient in many cases. The typical service life is around 30,000 to 50,000 operating hours. A clean environment and appropriate protection classes increase availability.

How can a cobot be integrated into existing processes, and how flexible is it afterward?

Cobots from ELITE ROBOTS can be integrated directly into existing workflows. They are compact, lightweight, and have standard interfaces for grippers, cameras, or conveyor technology. The robots can be repositioned, reprogrammed, and adapted to other products with little effort. This supports variant production, short setup times, and fast product changes.