Electrically and pneumatically operated directional control valves

Directional control valves can be actuated electrically or pneumatically. Both variants have the same task: they control how and where the compressed air flows in the system. The difference lies in the type of control.

Electrically actuated directional control valves receive a switching signal from a control system, for example from a PLC or a sensor. The valves switch quickly and accurately. They can be easily integrated into automated processes. Typical designs are 3/2, 5/2, and 5/3 directional control valves, as are often used in standard directional control valves. Depending on the design, different numbers of switching positions and connection options can be implemented.

Pneumatically operated directional control valves work with control air. They are mainly used where electrical control is not possible or where a large number of switching operations per minute are required. In simple versions, a return spring ensures that the valve returns to its original position after switching. In double pneumatically operated valves, each switching position is controlled by air, as is often the case with universal and application-specific directional control valves.

Which design is more suitable depends on the application. Electrically operated valves are flexible and can be easily integrated into control systems. Pneumatically actuated valves also work without electricity and switch particularly quickly. They are robust and ideal for systems with high switching frequencies or special safety and environmental requirements.

Learn more

5/2 directional control valve: Application and advantages

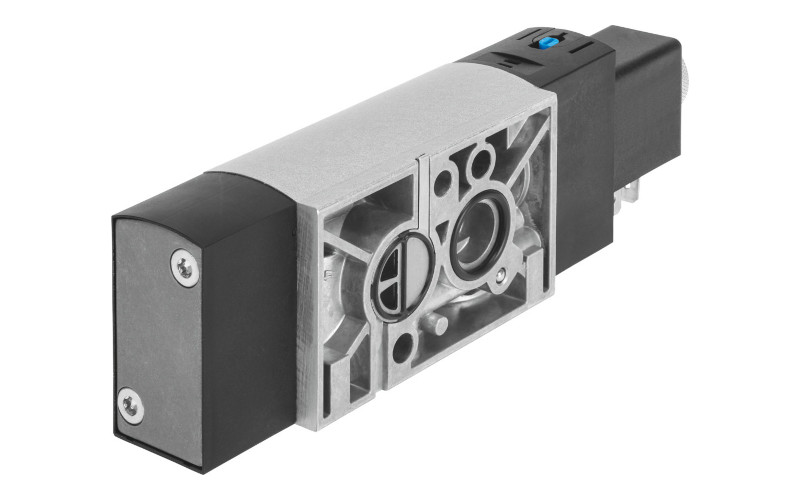

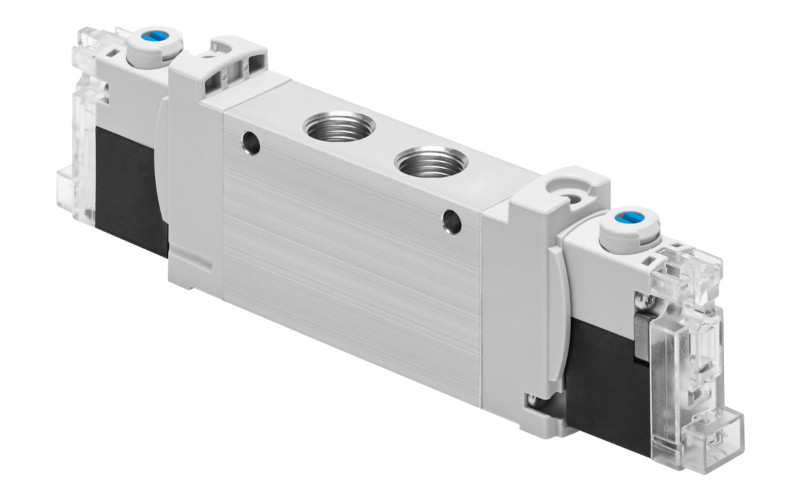

The 5/2 directional control valve is a commonly used valve type in pneumatics. It has five connections and two switching positions. This allows it to alternately direct the air flow to two sides of a double-acting cylinder. This enables reliable control of the cylinder's movement.

This valve is primarily used in automated systems, for example in mechanical engineering or in production lines. In these applications, it is important that movement sequences are repeated accurately and without delay. The 5/2 directional control valve ensures that cylinders switch direction clearly and change their position quickly.

Another advantage is its versatile control. Depending on the application, the valve can be operated electrically or pneumatically. It can be easily integrated into existing systems and is also well suited for compact installation situations. The design is space-saving without compromising on performance or durability. In applications with many switching cycles, the 5/2 directional control valve impresses with its robust design and short response times.

Learn more

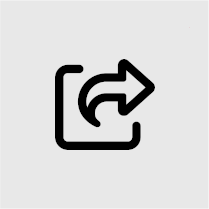

3/2 directional control valve: Simple, compact, proven

The 3/2 directional control valve is used for simple control tasks. It has three connections and two switching positions. In practice, this means that when activated, compressed air flows to the consumer. When the signal is switched off, the valve vents the line.

This type of valve is particularly well suited for single-acting cylinders or as a shut-off and vent valve. It is also frequently used in safety-related applications where defined air reduction is required.

Thanks to its compact design, the 3/2 directional control valve can be flexibly integrated into systems. It operates reliably and responds quickly. That is why it can be found in many handling systems, grippers, or clamping devices. Where simple control functions are required, this valve offers a robust and economical solution.

Learn more

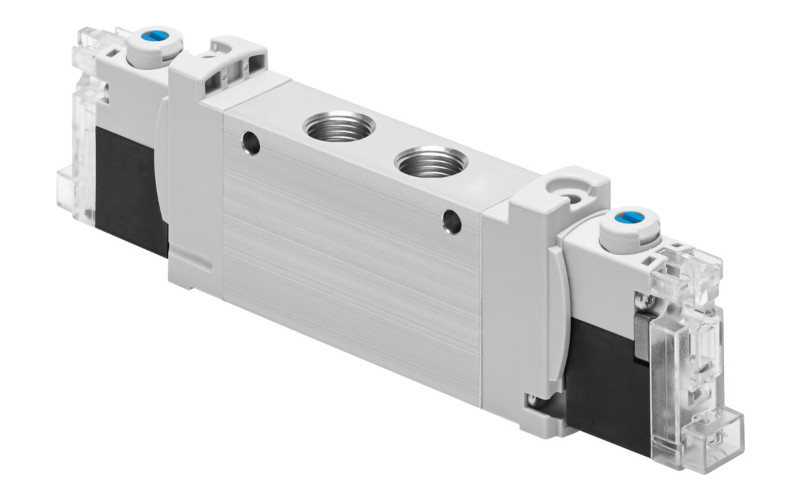

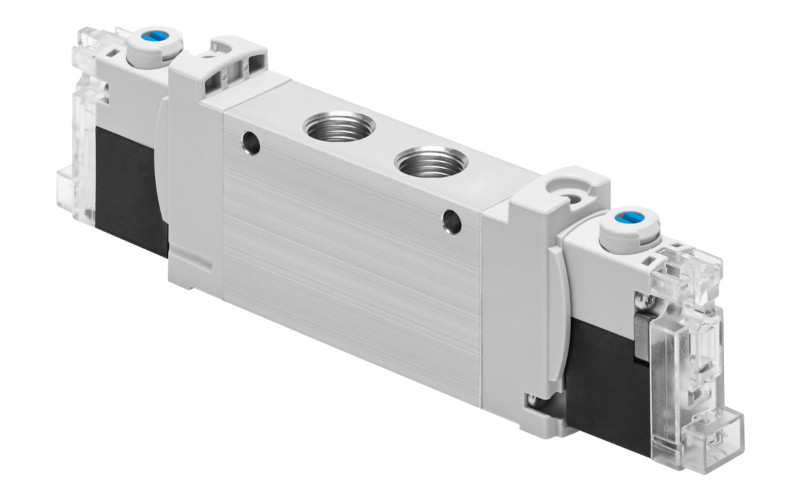

5/3 directional control valve: Three positions for greater control

A 5/3 directional control valve has five ports and three switching positions. It is primarily used when the control of a cylinder requires greater flexibility. In addition to forward and reverse stroke, it offers a center position that behaves differently depending on the design.

In this center position, the valve can completely block the air flow. However, it can also vent both sides of the cylinder or apply pressure on both sides. This allows the movement of the cylinder to be stopped, a position to be held, or the load to be relieved in a controlled manner.

These functions are particularly useful when movements need to be interrupted or held securely. Typical areas of application are machines with multiple cycle stages or applications with high safety requirements. The 5/3 directional control valve also offers a reliable solution for sensitive workpieces or changing loads.

Learn more

Proportional valves: Precise control for variable requirements

Proportional valves control pressure or flow rate continuously rather than in fixed stages. The valve opening adapts precisely to the control signal. Depending on the signal strength, the air flow is released to a greater or lesser extent.

This type of control is used wherever movements or pressures need to be adjusted with particular precision. This applies, for example, to positioning systems, variable speed cylinders, or the metering of small quantities of air or gas. Proportional valves respond flexibly to changing requirements. They maintain a constant pressure even when the load changes. This saves energy, reduces wear, and ensures stable processes. This makes them an ideal solution for applications with high precision and dynamic requirements.

Learn more