Reliable connections for industry and maintenance

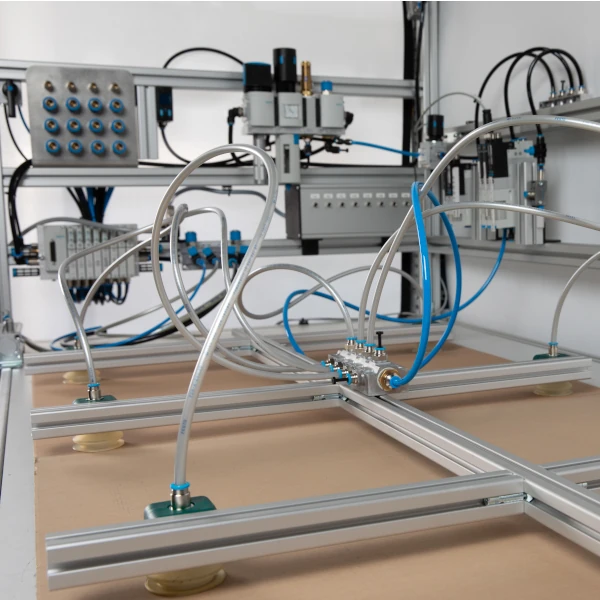

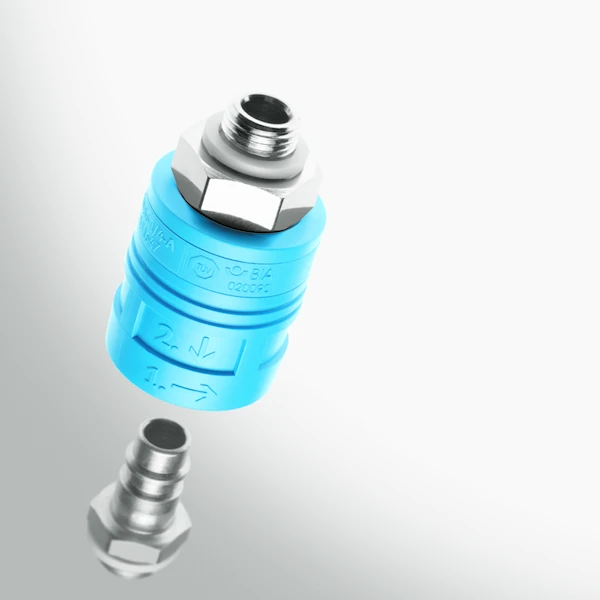

Pneumatic couplings are the interface between hoses, pipes, and devices. They determine how quickly a system can be converted, how securely the compressed air is held, and how smoothly the system operates. FESTO relies on tailor-made technology for industrial applications. Every component is designed and manufactured with precision.

Klefinghaus offers you the complete range: from simple quick couplings to multiple connections for complex systems. You get durable components that are easy to connect, reliable, and compatible with your existing system. We also support you in selection, replacement, and installation.