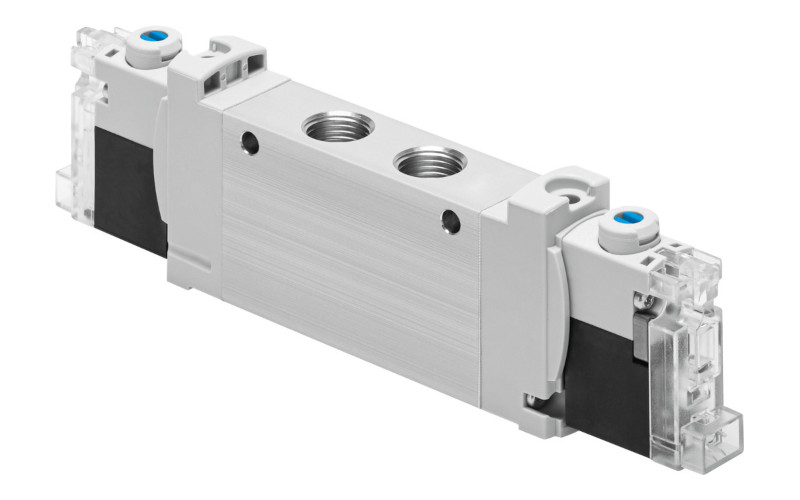

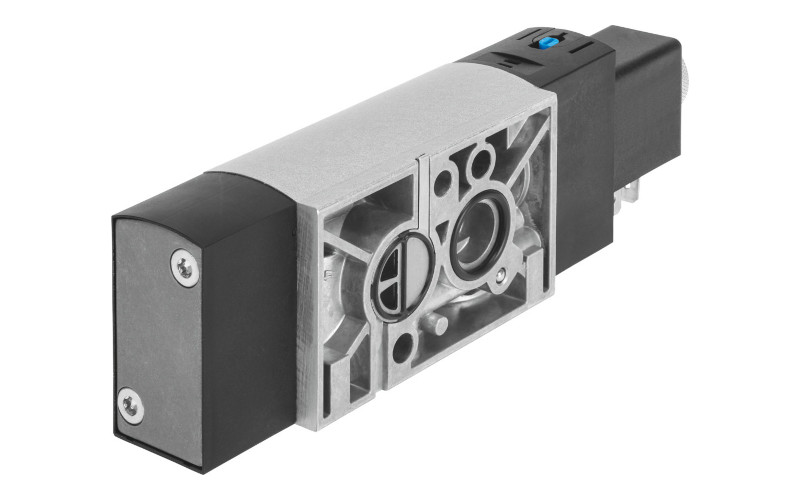

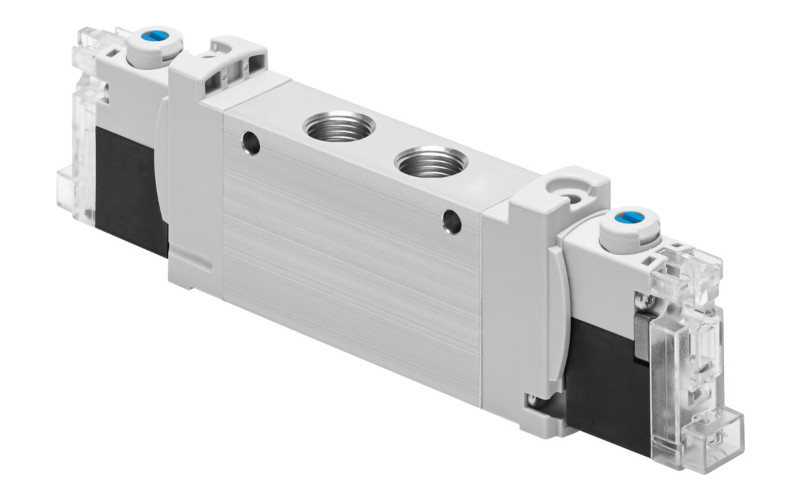

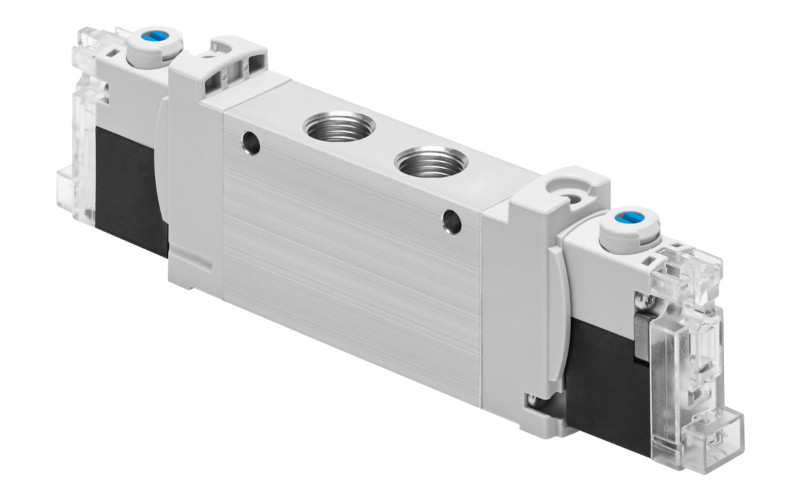

The right choice of solenoid valve depends on the specific system parameters, including medium, pressure, temperature, and switching function. Here you can find out how to proceed step by step to determine the right valve for your application.

1

Application analysis

First, clarify which medium is to flow through the valve. Also determine the pressure and temperature range in which your system operates. The desired switching function also plays a role. Is only an on/off valve required, or a switching function between several lines?

2

Material selection

Select the housing and seal material based on your application analysis. Stainless steel with PTFE seals is suitable for aggressive media or high temperatures. Brass and NBR are often sufficient for water and compressed air. Plastic can be a cost-effective alternative, especially in corrosive environments with low pressure.

3

Dimensioning

Next, determine how much volume should flow through the valve per unit of time. The so-called Kv value helps here. Also pay attention to the operating and differential pressure of your system so that the valve is neither overloaded nor underloaded.

4

Technical specifications

Check the voltage (e.g., 12 V DC, 24 V DC, or 230 V AC), the installation situation, and the desired response time. In time-critical applications such as automation or medical technology, a directly controlled valve with a fast switching time is recommended. If you want to save energy, choose coils with low power consumption. Alternatively, bistable valves are suitable, as they maintain their position even without a continuous current.

5

Safety requirements

Consider whether specific certifications are necessary. In the food industry, FDA-compliant materials may be required, while ATEX-certified valves are mandatory in potentially explosive atmospheres. Drinking water applications, on the other hand, often require DVGW approval.

6

Operating life and maintenance

Finally, it is worth considering the service life of the valve. High-quality materials and regular maintenance ensure reliable operation. Plan maintenance intervals and use robust seals if the valve is subject to heavy use.