Materials and their typical areas of application

Stainless steel is one of the highest quality materials used in valve manufacturing. It is characterized by particularly high durability and resistance. Stainless steel valves are mainly used in demanding environments, such as in the food and pharmaceutical industries, in chemical processes, or wherever aggressive media are used. Stainless steel remains dimensionally stable and reliable even at high temperatures and pressures. This makes it the first choice for long-lasting solutions, even though it is more expensive than other materials.

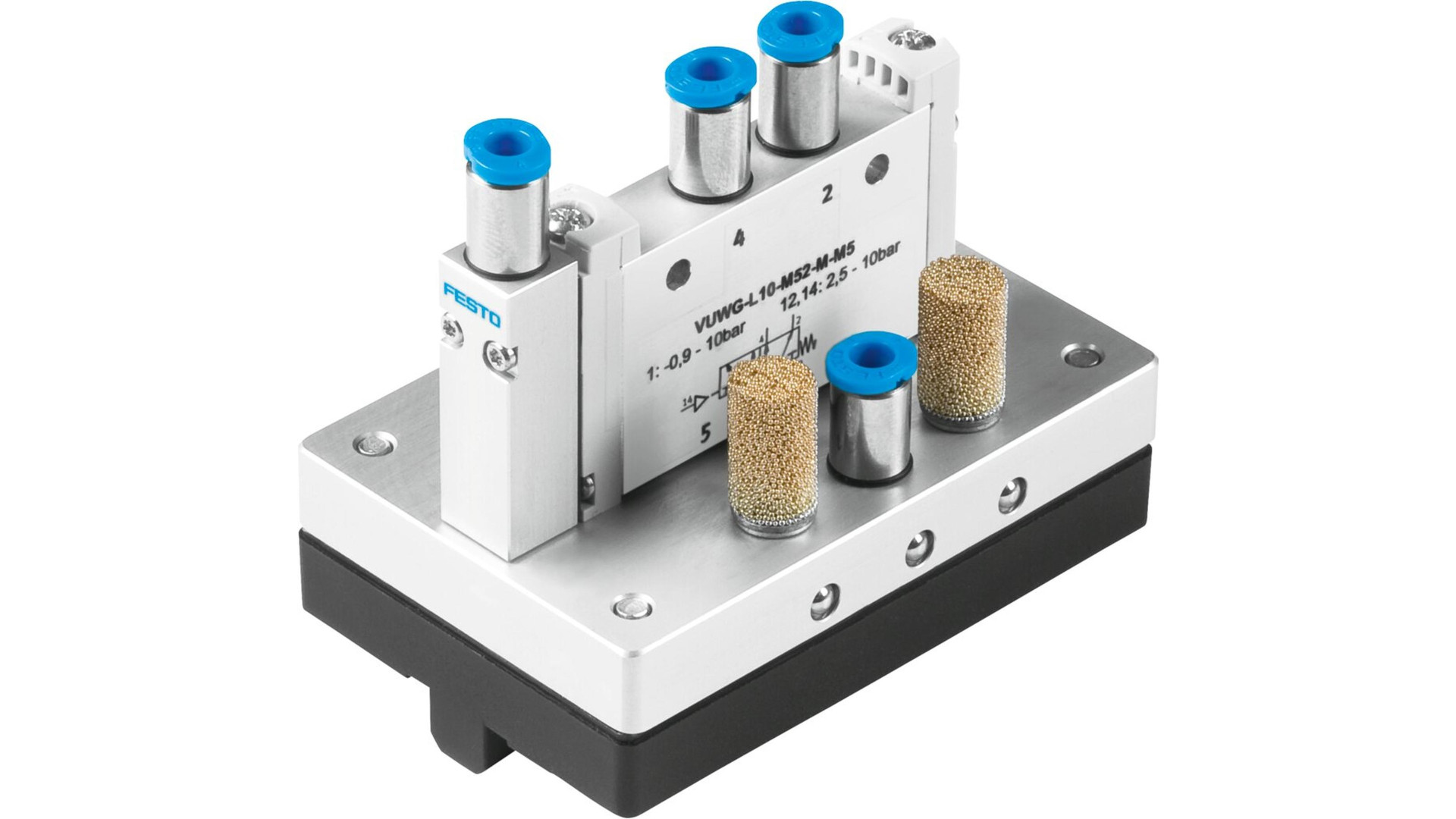

Brass is a proven standard material for many applications involving water or compressed air. It is easy to process, dimensionally stable, and offers a good price-performance ratio. Brass valves are used, for example, in heating systems, ventilation systems, and simple pneumatic control systems. However, brass is not suitable for aggressive media or very high loads, as it can corrode.

Plastics such as PVC or POM are primarily used in applications where weight reduction is required or the material must be resistant to certain chemicals. Plastic valves are lightweight, inexpensive, and often corrosion-free. They are used, for example, in water treatment or laboratory applications. However, plastic quickly reaches its limits at high temperatures or under mechanical stress. It is therefore only suitable for systems with low pressure and moderate loads.

Cast iron is used wherever valves have to withstand very high pressures or temperatures. Typical areas of application are large steam or water systems, for example in heavy industry or energy supply. The material is extremely resilient, but relatively heavy and susceptible to rust. A suitable coating is necessary to ensure its long-term use.

Bronze offers particularly good corrosion resistance, especially when in contact with salt water or drinking water. The material is durable, reliable, and is often used in shipping and sanitary systems. Compared to brass, bronze is more expensive, but significantly more resistant when it comes to sensitive or aggressive environments.