Pressure range

A pressure regulator limits the inlet pressure to a specified outlet value. To ensure reliable operation, the regulator must be designed for the actual operating pressure in the system. Pay attention to both the maximum permissible inlet pressure and the control range for the outlet pressure. In systems with pressure peaks or fluctuating supply, the regulator should have a certain safety reserve.

Flow rate

The amount of air flowing through the system has a significant influence on the choice of regulator. If the flow rate is too high for the selected model, the outlet pressure cannot be kept constant. If the regulator is oversized, this can lead to unnecessary energy consumption or imprecise control. Manufacturers specify the maximum flow rate of a regulator in liters per minute or cubic meters per hour.

Medium

In most cases, compressed air is used. However, some applications also use other gases such as nitrogen, oxygen, or CO₂. In these cases, it must be ensured that the regulator is approved for the corresponding medium. The resistance of the materials to moisture, oil, or chemical residues should also be taken into account.

Environment and temperature

The conditions at the installation site also influence the choice of controller. Special designs are required for high or low temperatures, humid or dusty environments, or contact with chemicals. Models with corrosion-resistant housings, suitable seals, and appropriate protection classes (e.g., IP65) ensure reliable operation even under difficult conditions.

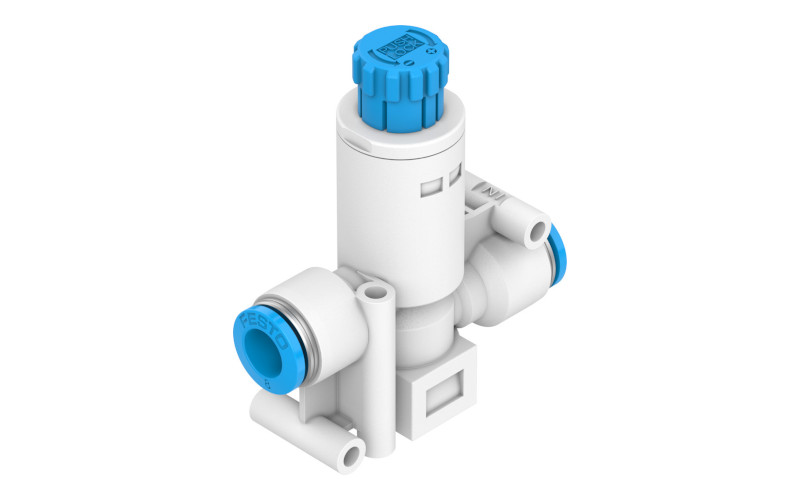

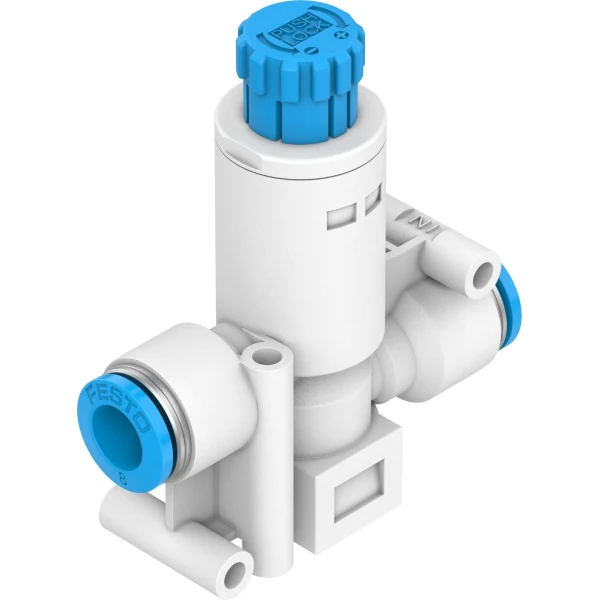

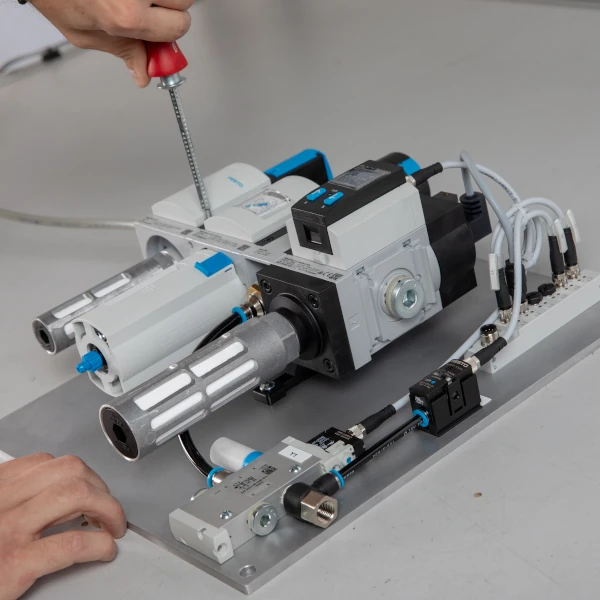

Design and connection

The regulator must be able to be integrated into the existing system – both mechanically and pneumatically. This includes suitable connection sizes (e.g., G1/4 or G1/2), the correct installation position, and sufficient space for operation or maintenance. The question of whether the regulator is part of a modular system or a stand-alone device can also be decisive for the selection.

Control function and application objective

Not every application has the same control requirements. If you simply want to maintain a constant pressure, a standard regulator will suffice. For sensitive processes or very low pressures, a precision regulator is recommended. If the pressure needs to be controlled flexibly, for example in automated systems or with changing loads, proportional or digital pressure regulators are the right choice.