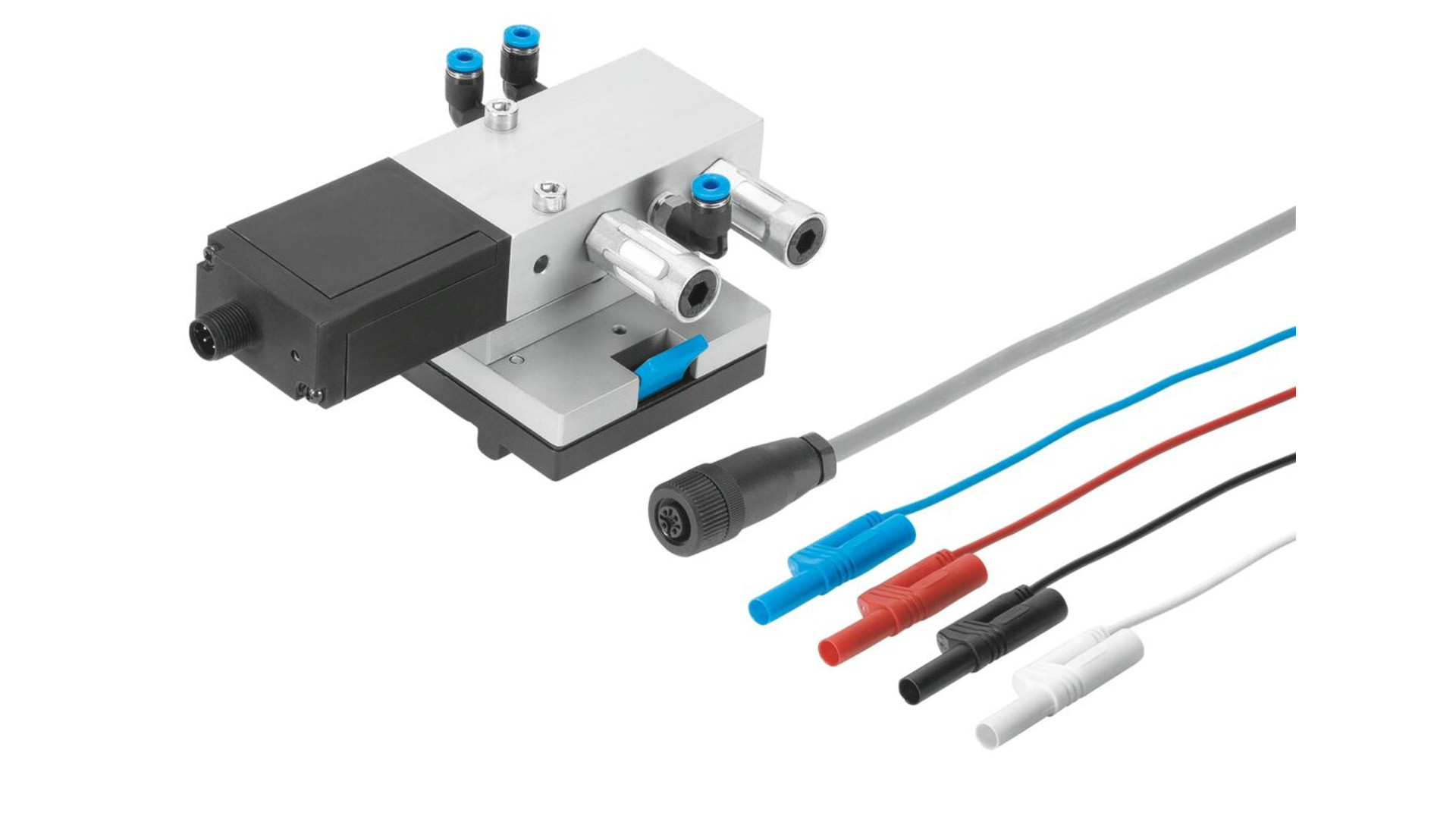

For a proportional valve to work reliably and precisely, it must be suitable for the respective application. These selection criteria will help you find the right proportional valve for your application.

1

Defining requirements

First, it should be clear what function the valve is to perform: Is it for regulating pressure, flow, or both? What media are used—air, oil, water, or special fluids? And in what operating range (temperature, environmental influences, installation position) will it be used?

2

Define control and signal type

Most proportional valves are controlled by an electrical control signal – analog (e.g., 0–10 V, 4–20 mA) or digital (e.g., PWM). In more complex systems, bus connections such as CANopen or EtherCAT are also possible. It is important that the control system is compatible with the existing infrastructure and the desired control quality.

3

Selecting the valve type

The selection of the appropriate valve type depends on the desired control behavior:

- Proportional pressure control valves maintain a constant pressure under changing conditions.

- Proportional flow control valves regulate the exact flow rate of gases or liquids.

- Proportional directional control valves also enable precise control of the flow direction.

- Proportional solenoid valves are characterized by particularly fast response times and high precision.

4

Observe installation conditions and maintenance requirements

In addition to the technical specifications, installation, accessibility, and maintenance requirements also play a role. FESTO proportional valves are designed for long-lasting and low-maintenance operation—even under demanding conditions.